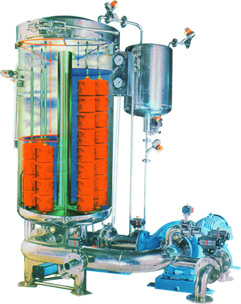

VENKTESHWARA HT/HP is a versatile dyeing machine for universal application treating material in various forms, such as packages, muffs, wrap beams, loose stock tops, All Venkteshwara Dyeing Machine are supplied with state of art technology with computerized Dye house management in duel version in Air pad and fully flooded system. VENKTESHWARA HT/HP is a versatile dyeing machine for universal application treating material in various forms, such as packages, muffs, wrap beams, loose stock tops, All Venkteshwara Dyeing Machine are supplied with state of art technology with computerized Dye house management in duel version in Air pad and fully flooded system.

VENKTESHWARA range of Dyeing Machines includes laboratory and small production machines. The range is 1kg to 1250kg. Designed for high operating Temp. 1400c and pressure 5 bar. All the models have same liquor ratio, functions, specific performance and are of the same modular design. They can be coupled together.

All the used for the manufacture of the Dyeing Machines, together with their components and equipment are made of AISI 316 & 316l stainless steel. |

|

|

Liquor Circulation : Is achieved by means of a high flow rate centrifugal pump with VFD drive. Variable liquor flow rate is made possible and optimum dyeing results depend upon the type of material being dyed and the type of dyestuffs used. With help of inverter drive it is possible to reduce electrical power consumption upto 30% as compared to fixed RPM motor drive. |

|

|

Reversal of Flow : Liquor flow direction is reversed automatically at present time intervals from inside out to outside in vise-verse according to requirement. |

|

|

Material to liquor Ratio : Programmable and adjustable M:L ratios in range from 1:4 upto 1:6 are possible. Lower liquor ratio means saving on cost of water, chemicals and energy consumption .The shorter the liquor ratio the lesser the cost of overall dyeing. |

|

|

Air pad system : By compress air static pressure is obtained and system is pressurized. Material carriers are fully flooded in the dye vat. |

|

|

Variable Loading: A high economic efficiency can be achieved with a constant liquor ratio by simply adjusting the filling level and by using the same material carrier smaller amount of material can be dyed. |

|

|

Heat Exchanger : Indirect heating and cooling coil is provided for rapid rise of temperature upto 40c per minute at steam pressure of 7 kg/cm2.Heating of liquor is homogenous for small capacity machine we will be provide the by compacting the Electric Heater . |

|

|

Service Tank : A Service Tank is provided for Feeding dyestuff and chemicals to the dye vat by means of an injection pump. At the top of the tank perforated pipe is mounted for washing of walls. |

|

|

Dispensing System : Linear as well as progressive dosing as per progressive dosing as per programmer is possible. |

|

|

Drain : Hot and cold drains have been segregated so that installation of heat recovery system is possible. High temperature drain provided so as to eliminate formation of Oligomers while using Dispersed dyes at high temperatures. |

|

|

Rinse : Overflow Rinse is provided to remove dirty liquor continuously by having through wash of material. |

|

|

Carriers : For cones and cheese, ropes, silver, tops, warp beams and loose stock with variable loading package carriers. |

|

|

Control Systems : Fully automatic computerized control system (with PLC) is supplied to increase productivity by reducing production cost and improve flexibility. It offers manual operation; logical function can be done manually .Along with the Machine, software of standard dyeing programs. Software for standard dyeing program for different type of material is provided or you may feed the new program as per your dyeing cycle operation by alpha numerical key board or from control panel. |

|

|

Eco-Friendly Machine : Since the pump and Carrier volumes are flooded and low water stream, power consumption and very limited effluents,this,machine is more, Ecology and Environment friendly. |

|

| VENKTESHWARA manufacturing pneumatic press in duel version 1) Simple Press 2) Motorize Press for package and Top & loose fibers suitable for pressing 25kg. to 1250 kg. |

|

| VENKTESHWARA manufacturing all type of HT/LT Panels, PLC Panels & Logic control Panels also undertake all type of Electric turnkey project. |

|

| OPTIONAL |

|

Sampling Device |

|

Full capacity preparation tank |

|

Hydro-Extraction in dye-vat |

|

On line PH value measuring and controlling system |

|

Automatic coupling system |

|

Dye Kitchen Equipment |

|

| |

| RANGE OF PRODUCT |

|

HT/HP Vertical Dyeing Plant Capacity 1kg to 1250kgs. |

|

Single package dyeing machine. |

|

Sample Dyeing Machine. |

|

Yarn Printing Machine(Space Dyeing) |

|

Package Carrier & Loose Fibers Carrier. |

|

Stock Tank. |

|

SS Dye Spring. |

|

Motorise Pneumatic press. |

|

Yarn Conditioning plant. |

|

HT/LT Panels. |

|

All type of Textile , Chemicals & Pharmaceuticals Machineries. |

|